The textile industry, one of the oldest and most established industries, is known for its laborious process of bringing ideas to life. With cutting-edge technology, it is currently undergoing a revolution that could impact fashion and upholstery. The industry employs millions worldwide and drives significant international trade. Technological advancements are driving changes as producers strive to streamline operations and meet consumer demand for textile products.

Textile Engineering

Textile engineering is a field concerned with the development, manufacture, and use of textiles, with an emphasis on creating aesthetically pleasing and tactile fabric structures. Advances in manufacturing, material processing, and design systems, as well as the use of new materials, are causing rapid change in the industry. Technology has improved weaving, dyeing, finishing, and printing processes, making fabric production more efficient, cost-effective, and environmentally friendly. The introduction of automation in the manufacturing sector could increase annual revenue by $4.9 trillion by 2030, according to an Oxford University report. Factors such as new materials and technologies, as well as expanding markets, are affecting textile production and distribution. The industry is currently vibrant and undergoing significant transformation through:

• The development of 3D knit technology, which makes textile products faster than before.

• Developments in robotics and automation.

• More environmentally friendly production methods.

• A shift in consumer demand for environmentally friendly goods.

The latest technologies in textile industry

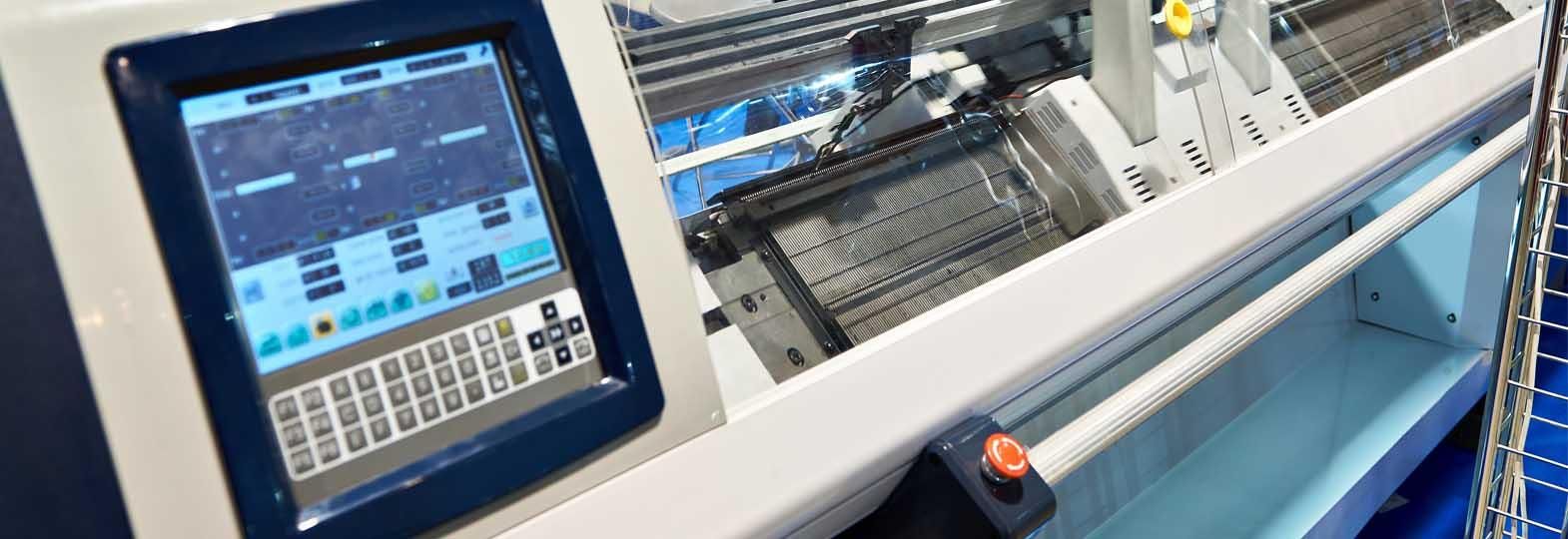

Digitally Enabled Automation: This is making a significant impact on the way businesses operate today, thanks to the development of smart technology and Internet-of-Things (IoT) technologies. By leveraging digital tools and technologies, organisations can automate mundane tasks, saving time and money while freeing up people to focus on more meaningful work. The days of manual, labour-intensive processes are gone, and streamlining can now be achieved with simple technology such as software robots, connected devices, and intelligent machines that communicate with each other to automate entire production lines.

Digital automation allows for data collection and analysis at an unprecedented scale, meaning that stock forecasting, customer service interactions, and employee engagement initiatives can be personalised like never before. These automated systems cut down on errors by eliminating human bias or oversight, enhancing the accuracy and reliability of delivery. In short, digitally enabled automation is transforming how people conduct business in the 21st century.

Smart Fabrics: These are specially designed to integrate technology into clothing. This can be achieved through various means, such as weaving nanotech or microscopic computers into the garment, or via coatings and treatments that give the fabric special properties. Smart fabrics can be used for a variety of purposes, from providing warmth when needed and protecting the wearer from UV rays and other harmful elements, to resisting stains and sweat build-up, and monitoring vital signs like heart rate and hydration levels.

Near field communication (NFC) and RFID tags are being used by fabric manufacturers to create “smart fabrics” that can actively adapt to environmental changes and will be incorporated into everything from clothes to bedding sets. They can also help control heat regulation by changing their air permeability based on temperature ranges or allowing greater airflow if necessary. Ultimately, smart fabrics aim to make life more comfortable and convenient by responding to changes in the environment around them while still being comfortable against a person’s skin.

Wearable Technology: This is being incorporated into many top clothing businesses’ products, offering customers next-generation personalisation possibilities that give them more control over how they appear and feel. Wearable technology is a type of technology that can be worn on a person’s body as an accessory or is used to enhance their everyday life. Wearable technology includes items such as fitness trackers, smartwatches, glasses, headphones, and even clothing. This revolutionary technology offers users the ability to monitor personal health and wellness, stay connected with their contacts, or access various apps such as maps or music, all while on the go. Wearable tech also gathers data from its activities like steps taken and heart rate, which can then be shared for further analysis with physicians or trainers for optimal health management. Many companies are investing time and money into research to make wearable devices available across many industries, including manufacturing, agriculture, healthcare, and military use. Through advancements in materials science and other fields, wearable technology has become essential in helping humans keep up with their day-to-day lives as well as finding ways to improve the efficiency and well-being of individuals around the world.

3D Printed Clothing: Several fashion designers are now focusing on 3D printed clothing as they develop their collections, because 3D printing technology provides a quick, affordable alternative for creating spectacular clothing designs. 3D printed clothing is a revolutionary new way of constructing apparel that involves using 3D printers to print designs onto textiles, such as nylon or polyester. 3D printers use specialised ink and fabric combinations to inject colourful designs onto garments.

The technology has the potential to revolutionise fashion and create more sustainable and affordable clothing options. Not only does it eliminate traditional sewing materials like thread, elastic, buttons, and zippers, but it also enables designers to customise the fit for individuals and incorporate intricate patterns into their designs. By virtue of 3D printing’s digital fabrication approach, small-batch production runs become possible with higher precision than manual labour could achieve.

This process also saves time, allowing for faster production with greater flexibility in terms of designs than conventional methods allow for. Another advantage of this method of clothing creation is its scalability; since the printer can be programmed with specific parameters, a single machine could be used to produce even complex garments quickly without needing too many replacements or costly machinery. All in all, 3D printed clothing offers excellent environmental savings due to production speed and lack of material waste while simultaneously providing exciting new opportunities for fashion innovation.

Virtual Fit Software: This provides a novel way of shopping for clothes through the use of digital technology to help customers visualise how clothing items would fit their bodies from the comfort of their homes. Retailers are now employing 3D imaging technology and AI algorithms to accurately measure specific body forms, even in-store. To use the software, customers take a picture of themselves in front of their computer camera and upload it onto the software, which then scans and measures their body to create a fitting image overlaid on the specific piece of clothing. This enables customers to see how the item fits before making a purchase, saving them time, money, and the inconvenience of poorly fitting clothes. Additionally, Virtual Fit Software offers visual feedback on how certain collections or styles look when worn by individuals with similar body types, enabling shoppers to make better-informed decisions when selecting clothing items.

How are the technological developments impacting textile industry?

Improved fibre quality: When it comes to creating new materials and fabrics, the textile industry has always been at the forefront of technological advancement. The degree of impurities, such as sand or plant debris, that a fibre contains can be used to judge its “fineness” or “cleanliness”, which impacts how soft and durable the fibre feels on the skin. Manufacturers are now able to produce fabrics of higher quality and with fewer impurities than those made even ten years ago, thanks to developments in textile technology. Finding novel approaches to raise the calibre of these fibres has been the subject of extensive research. For instance, developments in molecular biology have improved cotton fibre quality. New nanofiber materials have been developed as a result of nanotechnology research, which might ultimately help reduce the amount of water and energy consumed in manufacturing operations.

More efficient production methods: The introduction of new technological processes, such as 3D printing, has revolutionised production methods by allowing objects to be manufactured with greater speed, accuracy, and efficiency.

3D printing is based on the concept of additive manufacturing, which attempts to create physical objects from digital models without the need for traditional manufacturing techniques, such as machining or casting. This technology can reduce time-to-market, minimise material waste, and allow for the production of complex geometries that are not possible using traditional methods. It also permits the rapid prototyping necessary for businesses to constantly innovate, test ideas quickly, and create high-quality products in a short amount of time.

All in all, 3D printing has drastically streamlined manufacturing processes and enabled businesses to rapidly iterate on product designs, resulting in increased efficiency throughout the entire production process.

Faster replication of intricate designs on higher quality fabrics: Digital printing has revolutionised the fashion industry, allowing designers to quickly and accurately replicate intricate designs on higher quality fabrics. It works by using advanced inkjet technology to transfer image data from a computer directly onto fabric. This eliminates the need for expensive screens or film that was traditionally used in typical garment printing. An improvement in digital printing means that designers can achieve high-quality results with faster turnaround times, increasing efficiency and keeping costs low.

Additionally, digital printing offers greater precision when replicating intricate designs, making it ideal for complex patterns or artwork that require multiple colours. When compared to traditional methods of printing, digital printing results in brighter colours and finer details, creating a more vibrant overall design that captures people’s attention.

Automation of complex tasks: Automation of complex tasks, such as weaving and embroidery, is an important process for creating and improving textile materials. Automating these processes brings with it a plethora of advantages including higher levels of accuracy, reduced labour costs and increased productivity. By designing automated systems to take over repetitive tasks and help streamline operations, companies are able to allocate fewer resources towards manual craftsmanship while still achieving the desired quality of product. Automation also eliminates errors caused by human fatigue or lack of skill.

Additionally, automating complex tasks provides cost savings since machines produce faster than humans and require less maintenance. In summary, automation helps a business save money while increasing accuracy and productivity – all while reducing manual labour requirements. This system helps ensure that every product meets expectations while providing employees with more time to focus their efforts on other activities.

Enhancements in product testing procedures: Product testing procedures are crucial in ensuring that products meet the required quality and performance standards. Manufacturers can use various methods such as physical units, virtual simulations, and instrumented machines to evaluate product design, workmanship, components, material efficiency, and durability. Additionally, progressive testing can identify potential problems early on. With the help of test automation and data analysis techniques, companies can maintain greater control over the manufacturing process and achieve consistent quality across their product range.

Creating garments targeted at specific needs or user groups: Advanced yarns are specialised fibres and fabrics that offer improved performance characteristics, such as comfort, breathability, UV protection, moisture-wicking, and wind resistance. They are made from synthetic polymers, natural fibres, active minerals, and other advanced components. These textiles have the potential to create customised garments that cater to specific user groups, such as extreme sports enthusiasts or infants who need protection from irritants. By combining the right materials and production processes, sophisticated textiles can be created that offer enhanced comfort and protection. Thus, advanced yarns are a promising tool for apparel businesses to develop highly customised products for consumers.

Development of intelligent robotic systems: The development of intelligent robotic systems capable of performing various processing jobs, such as fabric cutting or assembling elements of clothing, is a challenge that requires research and innovation from robotics engineers worldwide. Such robots should be able to do more than just basic assembly tasks: they must be able to recognise different fabrics, measure them accurately and cut them according to the required specifications.

Moreover, they need to construct garments in an efficient and consistent manner. Programming a robot with complex algorithms will enable it to autonomously manipulate fabrics into their desired shape, while obeying all safety regulations. Robotics hardware platforms need to be further developed in order for the robot to handle different materials with precision and suitable mobility so that it can move along its designated task.

The ultimate goal is for intelligent robotic systems to become integrated into the clothes-making industry so that they can help reduce both costs and labour while providing consistent quality outputs.

Summing up

Digital technologies have revolutionised the textile industry, creating a wider market and providing better communication with customers. Information technology has advanced processes and materials that allow garments to be designed more efficiently and quickly, reducing costs for manufacturers. Online retail is driving further specialisation in the industry, offering customers a greater choice in personalising their apparel purchases. Additionally, digital technologies have enabled open platforms that can power virtual showrooms and give designers and manufacturers easier access to global markets.

Overall, digital technologies are having a major impact on the textile industry by allowing developments such as designs to be seen instantly without any physical presence, creating online selling platforms that result in faster production timelines throughout the supply chain, and promoting the use of renewable cotton/materials which can lower the cost of finished products. It can be rightly said that digital technologies are continuing to revolutionise every sector of commerce, including textiles. As these advancements become more commonplace in everyday operations, it is clear why technology has become an essential part of this ever-growing segment of business.

Comments